KL: Keynote Lecture (25 minutes)

IL: Invited Lecture (20 minutes)

OR: Oral Presentation (15 minutes)

PO: Poster Presentations (board size is 2mX1.26m. Fits A1 size and portrait A0 size).

Click on the presenter to view the abstract.

Click here to go back to ICBP2015 main page.

| June 24 (Wednesday) | |

|---|---|

| 18:30-20:30 | Registration & Welcome Reception (Venue: Suntec City Guild House) |

| Address: 3 Temasek Boulevard (Tower 5)

#02- 401/402 Suntec City Mall Singapore 038983 Click here for a map with some public transport directions, or here for the official website of the Suntec Guild House | |

Keynote Lectures

Biosynthetic PLA-related polymers improved by the metabolic engineering and enzyme engineering

Division of Biotechnology and macromolecular Chemistry,

Graduate School of Engineering -

Hokkaido Univeristy, Japan

Email: staguchi@eng.hokudai.ac.jp

From the viewpoint of realizing the environmentally eco-friendly society, biologically synthesized polyhydroxyalkanoates (PHAs) are attractive materials as bio-based alternatives to petroleum-derived thermoplastics. We developed a microbial platform carrying engineered PHA synthetic enzymes that confer high enantio-selectivity and broad substrate specificity toward monomeric constituents. The finding of an engineered PHA synthase with lactate (LA)-polymerizing activity (Lactate Polymerizing Enzyme, LPE) was a major breakthrough to achieve the microbial production of unusual polymers, particularly LA-based polymers. Poly(lactic acid) (PLA) is most widespread bio-based polymer because of its superior transparency and processability. Unlike the most of current chemical processes for PLA production including the LA fermentation and chemical polymerization of LA, our microbial processes produce LA-based polymers from renewable resources via one pot fermentation. In addition, the enzymatic polymer synthesis under mild conditions allowed us to obtain extremely high enantio-pure polymers (nearly 100% ee). We have also synthesized copolymers containing the other monomers with varied side-chain lengths of 3-hydroxyalkanoates (3HAs) using an evolved LPE.

In this talk, topics for the engineering approaches to synthesize new biopolymers will be introduced. Especially, combination of metabolic engineering and enzyme engineering are very powerful toolboxes. Recently, using liquid chromatography mass spectroscopy, we established the quantitative metabolite analysis procedure to address the rate-limiting step for synthesis of LA-based polymers. This new analytical system actually provided us with improved production of PLA-related polymers. This strategy should be applicable to a wide range of PHA-producing systems. It should be also noted that the unusual substrate specificity of LPE was found to be applicable to the synthesis of PLA-related polymers incorporating even other 2-hydroxyalkanoate (2HA) monomers; glycolate and 2-hydroxybutyrate. This finding further expands the structural diversity in microbial polyesters. Xylose utilization was also an effective for production of PLA-related polymers with respect to realizing the value chain system from raw biomass to value-added biomaterials.

Strategies for Implementing (Multi)functionality in Polymer-based Materials

Institute of Biomaterial Science, Helmholtz-Zentrum Geesthacht, Teltow, Germany

Institute of Chemistry, University of Potsdam, Potsdam, Germany

E-mail: andreas.lendlein@hzg.de

The successful usage of polymeric materials strongly depends on their ability to fulfill the specific and complex demands of applications. Scientific challenges originate from the need to tailor properties as well as to combine almost independent functions in one material system. In this presentation strategies are introduced to create bio-based polymer systems, in which different material properties and functions can be adjusted by only small variations in their chemical composition. Polymer network architectures allow modular approaches for the creation of multifunctional polymers on the molecular level. Three dimensional structures of shaped bodies, such as foams or multimaterial systems, offer additional options to implement further functions associated to different hierarchical organization levels. These principles are illustrated by examples such as gelatine-based 3D architectured hydrogels, active multimaterial systems with defined internal phase geometries or multiphase copolymer networks. Besides structural functions different shape-memory capabilities, degradability and biofunctionality are considered. Potential applications are discussed ranging from actuators to biomaterial based regenerative therapies and implants for minimally invasive surgery.

Current development of biobased polymers: Focusing on high-performance polylactides

Department of Biobased Materials Science, Kyoto Institute of Technology Matsugasaki, Sakyo-ku, Kyoto 606-8585, Japan

E-mail: ykimura@kit.ac.jp

Bio-synthesis of a number of key monomers (platform chemicals) such as succinic and itaconic acids has been progressing quite rapidly. Even terephthalic and adipic acids may possibly be replaced by the ones synthesized from biomass feedstock. Until now, not a few polymers have been synthesized from these bio-based monomers and chemicals. However, their application has been limited until now, mainly because of their lower cost-performance and inferior properties compared with the oil-based polymers. In particular, for replacing structural materials made of oil-based polymers, development of high-performance bio-based polymers having toughness and durability is required. We have recently shown that polylactides (PLA) consisting of controlled stereo-sequences of L- and D-lactates provide heat-resistant materials that are characterized by the high melting temperature (Tm) of 220-230 ºC, i.e., 50 ºC higher than that of PLLA. A typical example is the stereocomplex-type PLA (sc-PLA) formed in a mixture of poly(L-lactide) (PLLA) and its enantiomer poly(D-lactide) (PDLA). Another example is the stereoblock-type PLA (sb-PLA) consisting of PLLA and PDLA block sequences. In the former case the stereocomplex (sc) crystallization is likely accompanied by homo-chiral (hc) crystallization of PLLA and PDLA homopolymers, whereas the preferential sc crystallization can readily be performed in the latter case. In the 1st SSP process, a mixture of PLLA and PDLA having medium molecular weights is subjected to solid-state polycondensation (SSP). In the 2nd two-step ROP, the polymer prepared by the first polymerization of L- or D-lactide is subjected to the subsequent polymerization of the other enantiomeric lactide. In the 3rd polymer coupling route, PLLA and PDLA having anthracene and maleimide terminals are prepared and subjected to terminal Diels-Alder reaction. The sb-PLA polymers thus prepared can be utilized as the high-performance bio-based materials that retain sustainability. The development of biobased polymers as sb-PLAs ought to provide a new paradigm of polymer science and engineering.

Thermo-sensitive Hydrogel as Cell Carrier for Nucleus Pulposus Regeneration on Early Treatment of IVD Degeneration

Director,Institute of Biomed Eng & Nano-med, National Health Research Institutes, Taiwan

Tenure Distinguished Professor,Institute of Biomedical Engineering, National Taiwan University, Taipei, Taiwan

e-mail: double@ntu.edu.tw

Intervertebral disc degeneration usually starts at the nucleus pulposus. In the past decades, several techniques and prosthetics (artificial disc) have been developed to regenerate or replace the nucleus pulposus. However, these kind of pre-formed devices have to remove the nucleus pulposus and then replace an artificial one to relief the symptom of intervertebral disc degeneration. Recently, cell-based tissue engineering provides a rational approach to regenerate active nucleus pulposus cells (NP cells) to restore intervertebral disc architecture and function. However, the source of autologous nucleus pulposus cells are limited and their functional state does not favor regeneration. Besides, nucleus pulposus cells grown in monolayer may result in fibroblast-like transformation. Thus, the 3D hydrogel co-culture system maybe an alternative method to provide an adequate environment for nucleus pulposus cells proliferation, extracellular matrix production, cytokines secretion. In this study, we demonstrated that cell proliferation, total DNA and sulfated glycosaminoglycans synthesis of nucleus pulposus cells were significantly increased in the 3D hydrogel co-culture system. Furthermore, the extracellular matrix related gene expression and anabolism-related gene expression in 3D hydrogel co-culture system were significantly higher than other culture condition (such as monolayer culture or cultured in 3-D hydrogel without mesenchymal stem cells regulation).The gene expression of TIMP-1 and MMP-3 decreased in 3D hydrogel with mesenchymal stem cells co-culture system. This study suggests that the thermo-sensitive hyrogel could be an adequate material for nucleus pulposus cells proliferation and extracellular matrix production. Moreover, mesenchymal stem cells could regulate the isolated nucleus pulposus cells back to normal state through paracrine communications in the developed 3-D co-culture system.

Nanobiomaterials

Dept. of Mechanical Engineering, The University of Hong Kong, Pokfulam Road, Hong Kong

Email: memwang@hku.hk

The era of modern biomaterials began in the middle of the last century when major efforts were started on developing new materials specifically for biomedical applications. In recent years, nanoscience and nanotechnology have advanced rapidly and are making an enormous impact in the biomedical field. Using various nanotechnologies, nanobiomaterials are developed mainly along two directions: (1) nano-structured biomaterials, and (2) biomaterials of nano-sizes or nano-feature(s). Nano-structured biomaterials can provide desired properties which are not attainable with conventional, micro-structured biomaterials. On the other hand, biomaterials of nano-sizes or nano-feature(s) can affect/direct cellular and tissue responses. Nano- or micro-sized biomaterials can be used as drug, biomolecule or gene carriers for the targeted delivery and controlled and sustained release. Nanomedicine emerged a decade ago and involves using nanotechnologies to detect and treat diseases. For example, nanoparticles (polymer-, metal- or ceramic-based) have attracted great attention for their potential as diagnostic and/or therapeutic tools in oncology. A major direction in cancer nanotechnology is the design and development of multifunctional nanodevices, the so-called “theranostics”. Tissue engineering has made great advances over the past two decades and simple tissues such as skin or bone can now be successfully regenerated in the body. Researchers are now poised to tackle difficult problems such as the regeneration of complex human body tissues. Nanobiomaterials, nanomedicine and tissue engineering are high-impact developments in the engineering and medical fields from which huge benefits can be gained for both patients and the healthcare system. For more than 10 years now, we have been conducting research on nanoparticles, nanofibers and nanocomposites for biomedical applications, including theranostics and tissue regeneration. The nanoparticles, polymeric, metallic, ceramic or hybrid, are synthesized in different ways. Nanofibers are produced via electrospinning and used for tissue engineering or controlled release applications. We have investigated various techniques, including 3D printing, for fabricating nanocomposite tissue engineering scaffolds. Stem cells have been used for studying both cell-scaffold interactions and targeted cell differentiation as well as for evaluating the scaffolds. This presentation will give an overview of our research in nanobiomaterials and their applications in nanomedicine and tissue engineering. Some critical issues are discussed in the design and development of nanobiomaterials.

From Fundamentals to Applications: Biopolymer Engineering for Delivery of Active Molecules to the Skin, for Bone and Beyond

School of Chemical and Biomedical Engineering, Nanyang Technological University,Singapore 639457

Emails: SLim@ntu.edu.sg and TeohSH@ntu.edu.sg

INTRODUCTION: Biopolymers find applications in various fields raging from industrial and environment to medicine. In this talk we will focus on the engineering of protein-based and biopolymers as carriers to deliver active molecules to the skin for potential in wound healing and engineering micro architecture to trap stem cells for bone regeneration. The. protein-based material is formed by self-assembly of the subunits of pyruvate dehydrogenase multi-enzyme complex into hollow caged structure and is referred to as protein nanocage (PNC). The biopolymer polycaprolactone (PCL) has demonstrated implant applications in bone regeneration for more that a decade. Future incorporation of PNC into PCL membrane will expand the utility of PNC/PCL for extended release.

METHODS: The engineering of PNC interior, exterior, and inter-subunit interfaces is achieved through recombinant DNA technology. The cell penetrating ability of the engineered PNC was examined in vitro on keratinocyte cell culture and imaged using confocal microscope and flow cytometry. Applications of PCL biopolymers were carried out via 3D printing technology and bi-axial stretching.

RESULTS: The interior of the PNC is engineered to allow attachment of active ingredients while the exterior is decorated with skin penetrating and cell entering (SPACE) peptides. pH-responsive property for the release of active molecules from the interior has been achieved by modifying the inter-subunit interfaces of the PNC with the amino acid histidines. SPACE-decorated PNC shows enhanced cellular penetration.

DISCUSSION: Engineering of the carrier to deliver active molecules to the skin for wound healing application requires meticulous design. In this study we have shown that PNC can be engineered for encapsulation of active molecules with triggered release property. Cellular penetration is enhanced by decorating the PNC with SPACE peptides. Incorporation of the engineered PNC together with factors important in wound healing into PCL membrane will expand the utility of the biopolymer applications

Designing for end-of-life of Biobased Polymers - Understanding the Science and Role of Biodegradability and Recyclability in Material Design.

Department of Chemical Engineering & Materials Science, Michigan State University

Email: narayan@msu.edu

Biobased polymer materials/plastics offers the value proposition of removing carbon dioxide from the environment and embodying it into the polymer molecule via plant photosynthesis at a rate and time scale (1-10 years) that is in harmony with Nature’s biological carbon cycle. Petro/fossil carbon materials cannot be credited with any CO2 removal as they have been formed over millions of years. However, it is important that biobased materials have a clearly defined and environmentally responsible end-of-life option based on the application and end-use.

Recycling (chemical or mechanical) is a viable and important end-of-life option for non-biodegradable, durable, and recoverable products. Biobased PET bottles, PE containers, polyurethanes are exemplars – they are not biodegradable, but can be collected and recycled.

Designing for complete biodegradability in concert with a disposal system like composting (compostable plastics) and anaerobic digestion offers an environmentally responsible end-of-life for biobased polymer products. Biobased and biodegradable-compostable single use disposable packaging, particularly food packaging, disposable products and plastic ware is an "enabling technology" to divert food and other biowastes (40-50% of a country’s municipal solid waste) from landfills to environmentally responsible composting and anaerobic digestion disposal systems. Biobased and biodegradable agricultural plastics and mulch film also offer an environmentally responsible value proposition provided one can design for performance, cost and complete soil biodegradability in 1-2 year time frame.

The marine environment is NOT a disposal environment. There may be value if products that "inadvertently" enter into the marine environment are designed to be not persistent and utilized by marine microorganisms. However, they can persist over long time periods in ocean environments causing serious environmental and human health impacts.

Misleading and false biodegradability claims based on additives added into conventional polyolefin resins like polyethylene, polypropylene, and PET are proliferating in the marketplace and the scientific community needs to be proactively involved.

Updates on Bioplastic Developments in Korea: Industrial Perspective

Department of Polymer Science and Engineering, Inha University, Incheon, Korea

Korean Bioplastics Association, Korea

Email: ichin@inha.ac.kr

Research and development efforts of bioplastics in Korea has made significant achievement over the last couple of decades thanks to the government drive which strongly endorses biochemical business as one of the top-priority, new growth engines for the future Korea. However, although several chemical companies had actively engaged by investing in bioplastics, the bioplastic industry has not reached the economy of scale yet. Many bioplastic products on the market still rely on biodegradable feature; however, issues such as sustainability, renewability of resources and carbon neutrality are becoming more important. Thus, biomass-based plastics are gaining more attention by being increasingly used for semi-durable and durable applications. While Korea lacks in biomass feedstocks that are commercially available, a handful of companies and research centers have developed proprietary technologies to produce several different biomass-based monomers. In this lecture industrial development activities of representative chemical companies and research institutes in recent years will be reviewed. Status quo and future outlook of Korean bioplastic industry will be discussed in global perspective. Critical issues that need to be overcome to further grow the market will also be addressed.

Invited Lectures

Production of tailor-made Alginates by engineered Bacteria

Institute of Fundamental Sciences and MacDiarmid Institute for Advanced Materials and Nanotechnology, Massey University, Palmerston North, New Zealand

Alginates are polysaccharides composed of two building blocks, mannuronic acid and guluronic acid, and the sequence and arrangement of these monomers strongly impact their material properties. The mannuronic acid can also be acetylated. Physical properties can range from viscous solutions to self-assembling pseudoplastic materials. Its unique material properties and biocompatibility has led to uses as a viscosity regulator and stabilizer in foods, cosmetics and high-value medical applications including wound dressings, drug delivery systems and more recently in tissue encapsulation for regenerative therapy. Commercial alginates are extracted from brown algae and suffer from heterogeneity and lack purity. Increasing knowledge about bacterial alginate biosynthesis and our recent studies suggest the use of bioengineered bacteria to produce a range of defined and tailor-made alginates with desirable material properties. In this study, the membrane spanning multiprotein complex involved in alginate synthesis and modification was investigated with the aim to produced tailor-made alginates. For example, the protein-protein interactions and interactive role of membrane-anchored proteins Alg8 (polymerase) and Alg44 (co-polymerase) as well as periplasmic proteins AlgG (epimerase), AlgX (acetyltransferase) and AlgK (lipoprotein) on alginate polymerization and modification was studied by using site-specific deletion mutants, inactive variants and overproduction of subunits. The composition, molecular weight and materials properties of resulting novel alginates were analyzed. Interestingly the molecular weight was reduced by epimerization while it was increased by acetylation. Overproduction of Alg44, AlgG and the non-epimerizing variant AlgG(D324A) increased the degree of acetylation while epimerization was enhanced by AlgX and its non-acetylating variant AlgX(S269A). This study demonstrated that engineering of the alginate synthesis/modification multiprotein complex enables the production of various novel alginates.

Recovery of Polyhydroxyalkanoate from Bacterial Cells: Is there an Easier Way?

School of Biological Sciences, Universiti Sains Malaysia, Malaysia

Email: ksudesh@usm.my

INTRODUCTION: Polyhydroxyalkanoate (PHA) is a bacterial storage polyester accumulated as water insoluble granules in the cell cytoplasm. PHA has been researched extensively for its potential application as biodegradable plastics. The cost of PHA is currently high compared to similar polymers in the market, which hinders successful commercialization. Recovery and purification of PHA from bacterial cells are among the costly processes involved in the production of PHA.

METHODS: Cupriavidus necator cells were cultivated in mineral medium with palm oil or used cooking oil as the carbon source. The cells were harvested after 48-72 hours and freeze-dried. Dried cells containing poly(3-hydroxybutyrate) [P(3HB)] and poly(3-hydroxybutyrate-co-3-hydroxyhexanoate) [P(3HB-co-3HHx) granules were fed to animal models. The resulting fecal matter was collected and subjected to GC, GPC, DSC, TGA, rheology and protein analyses. Fecal matter was also subjected to further mild washing treatments with detergents.

RESULTS: The animal models used in this study readily consumed the freeze-dried C. necator cells that contained PHA granules and produced whitish fecal pellets. GC analysis of the fecal pellets revealed that they contained PHA of up to more than 90 wt%. Further washing treatments with detergents resulted in more than 95 wt% PHA. DSC, GPC and TGA analyses showed that the PHA granules recovered using this method had similar characteristics to the PHA obtained by chloroform extraction. However, the rheological properties of the PHA obtained from both these methods demonstrated clear difference. Proteins were detected in the biologically extracted PHA granules, which may be the reason for the observed differences in rheological properties.

DISCUSSION: The biological extraction method reported here is simple, scalable and can be integrated into some existing animal production systems. The resulting PHA may be suitable for some agricultural applications such as in the development of slow release fertilizer systems.

Production of lactic acid using thermophilic bacteria from lignocellulose

Institute of Chemical and Engineering Sciences, A*SATR, 1 Pesek Road, Jurong Island, Singapore 627833

Email: wu_jinchuan@ices.a-star.edu.sg

INTRODUCTION: The demand for optically pure lactic acid is increasing owing to the rapid growth of poly lactic acid (PLA) industry. Lactic acid is currently produced by microbial fermentation from starchy materials. To avoid the competition with the supply of foods and feeds, it is essential to produce lactic acid from lignocellulose, the most abundant renewable resource on earth.

METHODS: Oil palm empty fruit bunch (EFB) was hydrolyzed to get hemicellulose sugars by the combined use of dilute H2SO4 and H3PO4 in a 2-step process without any additional concentration steps, giving >110 g/L of total sugars in the hydrolysate. Furfural, 5-hydroxymethyl furfural and acetic acid in hydrolysate were sequentially degraded by simply adding the whole cells of the bacteria that were isolated from nature. Thermophilic Bacillus coagulans strains were isolated from the natural environment and used to convert all lignocellulose sugars to L-lactic acid at 50°C without the requirement of sterilizing the medium before fermentation.

DISCUSSION: In a simultaneous detoxification, saccharification and co-fermentation process, 80.6 g/L of L-lactic acid was obtained at a productivity of 3.4 g/L/h from total EFB including both hemicellulosic and cellulosic fractions. A 1-pot, 1-step process for simultaneous saccharification and fermentation (SSF) was developed to convert starch to L-lactic acid at 50°C under non-sterilized condition, giving 202 g/L of L-lactic acid from 200 g/L of corn starch. To reduce the nitrogen source cost for fermentation, expensive yeast extract was replaced with the same amount of cheap dry yeast achieving almost the same lactic acid titer, productivity and yield. Ca(OH)2 was found to be a better neutralizing agent to control the pH during fermentation than NaOH and NH4OH in terms of the higher lactic acid titer and productivity.

Amphiphilic Peptides That Mimic Nature – A versatile platform for combining and controlling biofunctional signaling, mechanical strength and chemical degradation

Dept of Chemical and Biomolecular Engineering ,National University of Singapore

The self-assembling behavior of peptide amphiphiles has been studied for over 20 years, and has been found to have interesting behaviors and applications. Recently, our group has worked on using these peptide amphiphiles to mimic nature in a multi-scale manner, from molecular signaling through receptor interactions, to hierarchical assembly that changes nanofibers into micro- and macro-fibers, and at the physiological level in controlling mechanical strength. The eventual goal is to mimic nature to produce synthetic materials that behaves like extracellular matrices with its corresponding biological, mechanical and chemical behavior and function. The peptide amphiphiles are more than a versatile platform, as it is also surprisingly simple to design a range of these functions through logical peptide selection and by learning from nature. We have achieved mimicry of ECM molecules from collagen to elastin, and from spider to silkworm silk. Our applications are currently aimed at tissue engineering of soft tissues such as liver and brain, to hard tissues of bone, and elastic tissues of the skin and fat.

Amino Acids Make 3HB-Based PHA Copolymers More Diverse

Tokyo Institute of Technology, Japan

Email: tsuge.t.aa@m.titech.ac.jp

Nowadays, over 150 different building blocks are known for polyhydroxyalkanoate (PHA). Poly[(R)-3-hydroxybutyrate], P(3HB), is the most common type of PHA but P(3HB) is brittle and has poor flexibility due to high crystallinity. Therefore, 3HB-based copolymers are now recognized as a practical material.

P(3HB-co-3-hydroxyvalerate), P(3HB-co-3HV), is the first developed copolymer; however, 3HB and 3HV are co-crystallized each other, thus, P(3HB-co-3HV) still has low flexibility. P(3HB-co-3-hydroxyhexanoate), P(3HB-co-3HHx), has more flexible than P(3HB-co-3HV), and has attracted a great deal of industrial attention in recent times.

Other than linear side-chain monomer units, amino acids can potentially provide diverse side-chain monomers such as branched side-chain and aromatic side-chain. For example, leucine and valine can provide 3-hydroxy-4-methylvalerate (3H4MV) unit, which has branched side-chain. Phenylalanine is also potential precursor for 3-hydroxy-3-phenylpropionate (3H3PhP) unit, which has phenyl side-chain.

These 3HB-based copolymers, P(3HB-co-3H4MV) and P(3HB-co-3H3PhP), exhibit better material properties than conventional P(3HB) and P(3HB-co-3HV). Additionally, almost of all PHA-producing bacteria possess complete amino acid biosynthesis pathways, thus, it would be possible to conduct metabolic engineering of amino acid biosynthesis pathway for supplying such amino acid-derived monomers. This presentation will cover mainly resent advantages in amino acid-derived PHA synthesis.

Effect of the electrospinning conditions on the higher-order structure and the stereocomplex formation of the PLLA/PDLA blend nanofibers

1*Dept. of Bio-based Materials Science, Graduate School of Science and Technology, Kyoto Institute of Technology, Kyoto 606-8585, JAPAN.

2Dept. of Mechanical Engineering, University of Malaya, 50603 Kuala Lumpur, MALAYSIA

Email: hyamane@kit.ac.jp

Nowadays, over 150 different building blocks are known for polyhydroxyalkanoate (PHA). Poly[(R)-3-hydroxybutyrate], P(3HB), is the most common type of PHA but P(3HB) is brittle and has poor flexibility due to high crystallinity. Therefore, 3HB-based copolymers are now recognized as a practical material.

P(3HB-co-3-hydroxyvalerate), P(3HB-co-3HV), is the first developed copolymer; however, 3HB and 3HV are co-crystallized each other, thus, P(3HB-co-3HV) still has low flexibility. P(3HB-co-3-hydroxyhexanoate), P(3HB-co-3HHx), has more flexible than P(3HB-co-3HV), and has attracted a great deal of industrial attention in recent times.

Other than linear side-chain monomer units, amino acids can potentially provide diverse side-chain monomers such as branched side-chain and aromatic side-chain. For example, leucine and valine can provide 3-hydroxy-4-methylvalerate (3H4MV) unit, which has branched side-chain. Phenylalanine is also potential precursor for 3-hydroxy-3-phenylpropionate (3H3PhP) unit, which has phenyl side-chain.

These 3HB-based copolymers, P(3HB-co-3H4MV) and P(3HB-co-3H3PhP), exhibit better material properties than conventional P(3HB) and P(3HB-co-3HV). Additionally, almost of all PHA-producing bacteria possess complete amino acid biosynthesis pathways, thus, it would be possible to conduct metabolic engineering of amino acid biosynthesis pathway for supplying such amino acid-derived monomers. This presentation will cover mainly resent advantages in amino acid-derived PHA synthesis.

Preparation of Novel Sustainable Polymers from Resin Acids and Plant Oils

Department of Chemistry & Biochemistry, University of South Carolina, Columbia, SC 29208, USA

Email: tang4@sc.edu

Sustainable chemicals and materials from renewable natural resources have a great potential in replacing petroleum-derived counterparts. Research in this field is becoming one of the cornerstones in polymer science for next generations and beyond. Natural molecular biomass plays an important role in the field of renewable polymers, as they can be directly used or derivatized as monomers for polymerization, in a way similar to many petroleum-derived monomers. This presentation will be focused on the synthesis of renewable polymers from a class of hydrocarbon-rich biomass by controlling macromolecular architectures for desirable applications. I will discuss the preparation of renewable thermoplastics and thermoplastic elastomers derived from natural resin acids (rosin), fatty acids and plant oils. I will also talk about how to utilize the unique structure and function of natural hydrophobic moiety for the development of novel antimicrobial biomaterials against a wide spectrum of bacteria including superbugs.

References

- Yao K.; Tang C. Controlled Polymerization of Next-Generation Renewable Monomers and Beyond. Macromolecules, 2013, 46, 1689-1712

- Jiang F.; Wang Z.; Qiao Y.; Wang Z. G.; Tang C. A Novel Architecture toward 3rd-Generation Thermoplastic Elastomers by a Grafting Strategy, Macromolecules, 2013, 46, 4772-4780.

- Ganewatta M. S.; Chen Y.-P.; Wang J.; Zhou J.; Ebalunde J.; Nagarkatti M.; Decho A. W.; Tang C. Bio-inspired Resin Acid-Derived Materials as Anti-Bacterial Resistance Agents with Unexpected Activities. Chem. Sci., 2014, 5, 2011 - 2016.

Controlled/Living Polymerization of Renewable Vinyl Monomers into Novel Bio-Based Polymers

Department of Applied Chemistry, Graduate School of Engineering, Nagoya University, Nagoya, Japan

Precursory Research for Embryonic Science and Technology (PRESTO), Japan Science and Technology Agency (JST), Japan

Email: satoh@apchem.nagoya-u.ac.jp

In this talk, the author will present the overview of our recent research topic in bio-based polymers by the controlled/living polymerization of naturally-occurring or -derived renewable monomers, such as terpenes, phenylpropanoids, and itaconic derivatives. The judicious choice of initiating system, which was borrowed from conventional petrochemical monomers, allowed not only the polymerization to proceed well but also afforded well-defined controlled/living polymers from these renewable monomers. We were able to find several controlled/living systems for the renewable monomers, which resulted in novel bio-based polymers including cycloolefin polymer, AAB alternating copolymer with an end-to-end sequence, phenolic and high-Tg alternating styrenic copolymer, and acrylic thermoplastic elastomer. For example, beta-pinene was cationically polymerized as alicyclic hydrocarbon monomers in a controlled fashion to result in a promising novel bio-based cycloolefin polymer. The beta-pinene or limonene underwent unprecedented 1:2 alternating radical copolymerization with maleimide derivatives, and the combination with a reversible addition-fragmentation chain transfer (RAFT) agent for the controlled/living radical polymerization resulted in end-to-end sequence-regulated copolymers with both highly-sequenced chain ends and main-chain repeating units as well as controlled molecular weights.

Chemo-enzymatic modification of microbial polyesters PHAs: preparation of thermoplastic or shape-memory block co-polymers

Department of Chemical & Biomolecular Engineering National University of Singapore, 4 Engineering Drive 4, Singapore 117585

Poly-[(R)-3-hydroxyalkanoates] (PHAs) are biodegradable and biocompatible materials produced by microorganisms. While these biopolyesters can be used directly for many applications, PHAs oligomers are excellent segments for engineering block co-polymers with desired material properties. We recently developed new concepts and methods for the preparation of PHAs-based block co-polymers with good thermoplastic or shape-memory properties for biomedical applications via chemo-enzymatic setting of PHAs oligomers. In this presentation, the following topics will be addressed: a) development of a green method for the preparation of thermoplastic block co-polyesters containing poly[(R)-3-hydroxybutyrate] (PHB) and poly[(R)-3-hydroxyoctanoate] (PHO) blocks via enzyme-catalysed polycondensation of telechelic PHB-diol and PHO-diol with divinyl Adipate; b) development of a new synthetic method for the preparation of thermoplastic di-block co-polyesters containing PHB and poly(ε -caprolactone) (PCL) blocks via enzyme-catalysed ring-opening polymerization of ε-caprolactone with PHB-diol; c) preparation of novel thermoplastic di-block co-(polyester-carbonate) containing PHB and poly(trimethylene carbonate) blocks via enzyme-catalyzed ring-opening polymerization of trimethylene carbonate with PHB-diol; and d) synthesis and characterization of novel biodegradable shape-memory block co-polymers containing PHBV hard block and hyperbrached MDI-linked PCL switching block as fast self-expandable stents.

Synthesis and Characterization of Biobased Copolyester Containing Biomass Monomer

Department of Nano and Organic engineering, Faculty of Engineering, Hanyang University, Seoul, Korea

Abtsrcat not available online.

Syntheses and Structure of Copolymers with Alternating Sequences of 3-Hydroxybutyrate and Lactate Units

Bioplastic Research Team, RIKEN Center for Sustainable Resource Science, Japan

Email: habe@riken.jp

We focused the structure and physical properties of alternating copolymers consisting of α-hydroxyl acid monomeric unit of lactate (2-hydroxypropionate: 2HP) and β-hydroxyl acid monomer unit of (R)-3-hydroxybutyrate ((R)-3HB). Taking into account the chiral structure of monomeric units, two types of stereoisomeric dimers ((R)-3HB-(R)-2HP and (R)-3HB-(S)-2HP) were respectively prepared, and the alternating copolymers with different stereocompositions were synthesized from the dimeric monomers by condensation reaction. Based on the NMR analyses, it was confirmed that the obtained copolymers had an alternating sequence of (R)-3HB and 2HP units. In contrast to random copolymers of (R)-3HB and 2HP units, the repeating sequence of alternately connected (R)-3HB and 2HP units formed crystalline region. The copolymer with alternating sequence of (R)-3HB and (S)-2HP units had a melting temperature at 83 °C. On the other hands, the melting temperature of copolymer of (R)-3HB and (R)-2HP units was quite higher than those of the corresponding homopolymers (around 180 °C) and reached to 233 °C. When the alternating copolymers were prepared from a mixture of stereoisomeric dimers, both the melting temperature and crystallinity varied in the wide ranges depending on the composition of stereoisomeric dimmers. In addition, the crystalline structure of alternating copolymers was characterized from the X-ray and electron diffraction patterns of lamellar singe crystals. The relationship between the crystalline structure and thermal properties in the alternating copolymers were discussed.

Dynamic Covalent Polymers from Bio-based Furan

Institute of Industrial Science, The University of Tokyo, Komaba, Tokyo 153-8505, Japan

E-mail:yoshie@iis.u-tokyo.ac.jp

A bio-based polyester, poly(2,5-furandimethylene succinate) [PFS], was prepared from bis(hydroxymethyl)furan and succinic acid, both of which are obtainable from biomass. This polyester possesses many furan rings in the main chain, allowing the formation of reversible cross-links by the Diels-Alder reactions with bis-maleimido [M2]. By controlling the amount of M2, the networked furan polymers, PFS/M, with a wide variety of properties were obtained. They include relatively hard materials with a yield point and flexible elastic ones. Among the networked furan polymers, the elastic ones had good self-healing ability: when it broke, their surfaces could be rejoined without any external stimulus at room temperature. Healing was more effective when the broken surfaces were activated by a solvent (chloroform) or by an M2 solution. For example, PFS/M2 with furan-to-maleimide ratio of 6/1 recovered as much as 74% of the toughness of the original sample by self-healing and over 90% of the toughness by treatment with chloroform or 70 g l−1 M2 solution. To the best of our knowledge, this is the first report on the room temperature self-healing of furan−maleimide polymers. Further, the network polymers show unique multi-shape memory controlled by local glass transition temperature. Local glass transition temperatures of a PFS/M film were changed by immersing sections of the film in a M2 solution with a different concentration. Each section memorizes a temporary shape, which recovers its permanent shape at a different recovery temperature depending on the local glass transition temperature. The PFS/M polymer offers the possibility of materials having practical mechanical properties and unique functionalities of self-healing and shape memory.

Construction and New Applications of Biomass-based Cyclic Polylactones

Institute of Chemical and Engineering Sciences, 1, Pesek Road, Jurong Island, Singapore 627833

Email: zhu_yinghuai@ices.a-star.edu.sg

Biodegradable polymers produced from renewable resources such as lactones, attract growing interest and become more important both in academia and industry. These materials have high potential to replace the existing fossil oil-based materials in many areas such as in packaging and agriculture due to the depletion of fossil oil in future [1,2]. In our lab, we are developing biodegradable materials in synthetic methodology and looking for new applications of cyclic polylactones [3,4]. Cyclic polymers have unique properties and inherent advantages such as low melting viscosity, controllable Mw and rapid crystallization when compared with long-chain-based linear polymer architectures [5]. Therefore, the cyclic polymers are expected to find specific applications in microelectronics, textiles, biomedical and pharmaceutical industries, as well as catalysis. In the presentation, we report the preliminary results regarding synthesis and application as catalyst support of cyclic polylactone-clay hybrid. The hybrid has been prepared by a zwitterionic ring opening polymerization catalyzed by in situ generated N-heterocyclic carbenes. The resulting hybrid has been found a good support for palladium nanoparticles-based catalysts [4,6].

References

- Dechy-Cabaret, O.; Martin-Vaca, B.; Bourissou, D. Chem. Rev. 2004, 104, 6147.

- Kamber, N. E.; Jeong, W.; Waymouth, R. M.; Pratt, R. C.; Lohmeijer, B. G. G.; Hedrick, J. L. Chem. Rev. 2007, 107, 5813.

- Prasad, A. V.; Stubbs, L. P.; Ma, Z.; Zhu, Y. J. Appl. Poly. Sci. 2012, 123, 1568.

- Prasad, A. V.; Zhu, Y. J. Appl. Poly. Sci. 2013, 128, 3411.

- Y. Zhu, N. S. Hosmane, Chemistry Open, 2015 manuscript accepted.

- Y. Zhu, N. S. Hosmane, Coord. Chem. Rev. 2015, on-line.

Interfacial Polyelectrolyte Complexation Fibers for Tissue Engineering

Institute of Bioengineering and Nanotechnology, 31 Biopolis Way, The Nanos, Singapore 138669

Chitin, the second most abundant natural polymer after cellulose and a constituent of shellfish exoskeleton, and alginic acid, a well-studied biopolymer commonly derived from seaweed, form the basis of a fiber type that our laboratory has extensively investigated for biomedical application. Interfacial polyelectrolyte complexation (IPC) fibers are drawn from the interface of two oppositely charged polyelectrolytes. Being a mild, aqueous-based process, IPC is amenable towards the encapsulation of cells at near-neutral pH solutions, providing a 3D matrix that is permissible to both cells and the factors that support their viability and function. We have used IPC fibers for stem cell expansion and differentiation, to create pre-vascularized constructs for tissue engineering, and to set up 3D in vitro models for drug screening. While our earlier efforts were based on the use of non-woven scaffolds, we have since developed multicomponent fibers and fiber-assembly processes that allow us to spatially pattern biological components in three dimensions, to recapitulate cell-cell and cell-ECM interactions that are necessary in the tissue engineering endeavor.

Uses of Agricultural Waste Product, Silk Sericin, in Medical Applications

Department of Pharmacy Practice, Faculty of Pharmaceutical Sciences, Chulalongkorn University, Bangkok, Thailand

Silk derived from the silkworm Bombyx mori is composed of two major protein components, fibroin and sericin. Fibroin is a fibrous protein, presented as a delicate twin thread linked by disulfide bonds, enveloped by sericin with successive sticky layers that help in the formation of a cocoon. Sericin or silk glue constitutes 25–30% of silk protein. It contains 18 amino acids, most of which have strong polar side chains as hydroxyl, carboxyl and amino groups made it easily soluble in water. Sericin has been studied for various potential applications because of its unique biochemical and biophysical properties, including biocompatibility, biodegradability, antibacterial, antioxidant, anti-tyrosinase, anticancer, UV light protecting activity, coagulant and moisturising.

We have found that sericin can activate collagen production from fibroblast cells. Due to that property, sericin has been widely investigated for its use as wound healing material. The results from clinical study showed that silk sericin scaffold and silk sericin cream can significantly promote partial-thickness wound healing compared to commercial, standard wound dressing. Since sericin can suppress interleukin and tumor necrosis factor production, it show not only benefit in wound care, but applying sericin cream can also reduce the itching intensity of the skin in hemodialysis patients and can be used as a treatment choice for psoriasis. The mechanism of action of sericin in reducing oxidative stress and COX-2 made it applicable for decreasing skin tumor incidence and tumor multiplicity from ultraviolet B damages.

Consumption of sericin also shows benefit in clinical applications. In vivo study indicated that sericin, especially low molecular weight one, can reduce colon tumorigenesis by activate apoptosis of cells. It also can reduce high blood sugar level in diabetic patients which will be useful if use as adjunct therapy. In hyperlipidemia rats, sericin can significantly reduce low density lipoprotein and triglyceride levels while increase serum high density lipoprotein level.

From agricultural waste, broad applications of sericin were found both in cosmetic and medical uses. Further investigation, especially in clinical study, needs to perform in order to determine the dose and confirm the results. Use of sericin not only provide a new choice of medical material, but also reduce the pollution causes from discarding this waste into the nature.

Water-based Chitosan for Bio-sensors and Detection Systems

1The Petroleum and Petrochemical College, Chulalongkorn University

2Department of Anatomy, Faculty of Medicine, Chulalongkorn University

3Department of Microbiology, Faculty of Medicine, Chulalongkorn University

4Center for Petroleum, Petrochemical, and Advanced Materials, Chulalongkorn University, Bangkok 10330, Thailand.

Email: csuwabun@chula.ac.th

INTRODUCTION: Chitosan is known as the only natural occurring polysaccharide with the reactive functional groups, i.e. hydroxyl and amine groups, to lead to the bio-related properties, cationic properties and the various derivatizations. However, the fact that chitosan has the strong inter- and intramolecular hydrogen bonds, it is insoluble in most solvents except carboxylic acids. Thus, most chemical modifications of chitosan are rather complicated with multi steps in harsh conditions and required the many organic solvents. The uses of chitosan in biomedical field, though it is the way for the advanced and value-added applications, did not get much attention as it should be. The present work focuses on a simple chitosan conjugating reaction in water to propose the water-based sensors and detection systems for biomolecules.

METHODS: Chitosan water soluble was prepared by simply mixing with hydroxybenzyltriazole (HOBt) or N-hydroxylsuccinimide (NHS) in equimolar. The conjugating reaction was further carried out at room temperature with carboxyl group containing molecules, i.e. oxanorbonadiene, poly(N-isopropyl) acryamide (PNIPAM), thymine, and protein (antibody). For chitosan-antibody, chitosan was coupled with magnetic nanoparticles using silane coupling agent in prior step. Each product was dialyzed and the functions as the bio-sensors or the bio-detections were investigated.

RESULTS AND DISCUSSIONS: Chitosan-oxanorbonadiene rapidly changes the pink color of azido-gold nanoparticles to violet as a consequence of copper free Click and this can be used as antigen detection system. Chitosan-PNIPAM entraps and releases magnetic nanoparticles (MNPs) by simply changing the temperature at its LCTS (~37 °C). This enables the release of MNPs out of the species in need after finishing the use of MNPs in the extraction process. Chitosan-thymine shows the strong interaction with poly(A), DNA, and RNA as identified from electrophoresis technique. This implies the potential application of the simple gene identification.

All-celulose Composites and Nanocomposites

Dept. Chem. Sci. & Eng.,

Graduate School of Engineering

Kobe University, Japan

Email: tnishino@kobe-u.ac.jp

Composite materials, typically glass fibers or carbon fibers embedded into epoxy resin or unsaturated polyester, show excellent mechanical and thermal properties; thus, they are widely used in various applications ranging from aerospace to vehicles to sports utensils. However, these advantages cause environmental problems when disposing by incineration. Consequently, there are growing demands for environmentally friendly composites. Paradigm shift from energy consuming materials to sustainable materials has brought increasing importance of biomass utilization. Biofibers are among the most keenly required materials of the twenty-first century.

In general, composites are composed of two chemically different materials. The interface between the incorporated fiber and the matrix often causes problems, such as poor compatibility, insufficient stress transfer, and high water uptake. If the fiber and the matrix are both made of the same material, benefits such as recyclability and good adhesion through the perfect interface can be expected. A recent emerging concept of all-cellulose composites, where the reinforcement and matrix are both cellulose, has received increased attention.

The average strength of 480 MPa for the all-cellulose composite was comparable or even higher than that of conventional glass-fiber-reinforced composites. In addition, modulus is comparable with that of Mg alloy, frequently used as light weight alloy for electric devices. In addition, the all-cellulose composite is optically transparent, because of all composed of single component (cellulose) and interface free structure. The all-cellulose composite is totally composed of sustainable resource, biodegradable after the service, which gives it advantages with regard to disposal, composting, and incineration. It possesses excellent mechanical (high modulus / high strength), thermal (high heat resistance, low thermal expansion) and optical performance (high transparency) during use.

The procedure, structure and properties of all-cellulose composite and nanocomposite would be reviewed.

Structural and Material Design of Cellulose Paper Composites

The Institute of Scientific and Industrial Research, Osaka University, Japan

Email: hkoga@eco.sanken.osaka-u.ac.jp

INTRODUCTION: Flexible and wearable electronics has recently attracted increasing attention, because it can open up new possibilities for next-generation portable devices. Opaque or transparent paper materials, which are prepared from cellulose pulp fibers or nanofibers, respectively, have been regarded as promising substrates alternative to conventional glasses and plastics for flexible electronic devices. The unique features of the paper include renewability, biodegradability and porous structures. Here we present flexible paper electronics, such as transparent conductive paper, prepared by using paper-specific porous structures.

METHODS: For preparation of transparent conductive paper, an aqueous suspension of cellulose nanofibers was first dewatered on a membrane filter under suction filtration. Subsequently, an aqueous suspension of silver nanowires or carbon nanotubes was poured and filtered in the similar manner. The resulting wet sheet was covered with a hydrophobic glass, followed by hot pressing at 110°C for 20 min (1.1 MPa) and peeling from the membrane filter.

RESULTS: Uniform coating of silver nanowires and carbon nanotubes was achieved by simple filtration of their aqueous dispersions through the cellulose nanofiber paper, which acted as both filter and transparent flexible substrate. The as-prepared silver nanowire networks on the nanopaper offered sheet resistance of 12 Ω sq-1 with optical transparency of 88%, which was up to 75 times lower than the sheet resistance on a plasrtic film prepared by conventional coating processes.

DISCUSSION: These results indicated that the ‘filtration coating’ provides uniformly connected conductive networks because of drainage in the perpendicular direction through paper-specific nanopores, while conventional coating processes inevitably cause self-aggregation and uneven distribution of the conductive nanomaterials because of the hard-to-control drying process, as indicated by the well-known coffee-ring effect. This filtration process is expected as an effective coating approach for various conductive materials. The transparent conductive nanopaper is a promising material for future paper electronics.

Dispersion and Interaction of Graphene oxide in Poly(3-hydroxybutyrate) Nanocomposites

Department of Chemistry, Polymer & Materials Chemistry, Lund University,Lund, Sweden

Email: frans.maurer@polymat.lth.se

INTRODUCTION: The modification of physical properties of P3HB by the incorporation of small amounts of graphene oxide (GO) was explored, with the aim to widen the application range of P3HB and to modify its rheological behavior.

METHODS: Several important physical properties could be measured as a function of GO content with the following characterization techniques; SEC, X-ray diffraction, DSC, TGA, Dynamic Rheology and Positron Annihilation Lifetime Spectroscopy (PALS). The samples were prepared by solution mixing, by evaporation of the solvent and finally pressing of the dry samples during 2 min at 180°C.

RESULTS: Rheological measurements were performed as a function of time at 185oC, facilitating the determination of an equilibrium modulus characteristic for the network structure formed by the GO particles. A power law dependence of the equilibrium moduli as a function of volume fraction was observed. The decomposition temperatures determined with TGA were not affected by GO in the P3HB nano-composites. The heat of fusion and crystallinity were slightly reduced as a function of GO content. PALS gives information about the free volume hole sizes in the amorphous phase of the semicrystalline P3HB nano-composites. The hole sizes strongly increase with amount of GO, indicating that strong hydrostatic stresses on the free volume cavities exist, induced by large differences in shrinkage of GO and the polymer during preparation of the samples.

DISCUSSION: Large changes of rheological and other important physical properties are observed when adding 0.01- 5 wt% graphene oxide to P3HB. Network formation of the nano-particles is observed and can explain the peculiar rheological behavior of the nano-composites. Dispersion of GO and interaction of GO with the P3HB matrix are major factors determining the other physical properties measured.

Engineering Protein-based Nanoparticles for Delivery of Active Molecules to the Skin

School of Chemical and Biomedical Engineering, Nanyang Technological University 70 Nanyang Drive, Block N1.3, Singapore 639457

*Emails: SLim@ntu.edu.sg and TeohSH@ntu.edu.sg

INTRODUCTION: Protein-based nanoparticles are amenable to chemical and genetic modifications. In this talk we will focus on the engineering of a model protein-based nanoparticle, E2 protein, as carriers to deliver active molecules to the skin. The E2 protein is formed by self-assembly of sixty subunits of pyruvate dehydrogenase multi-enzyme complex into hollow caged structure and is referred to as protein nanocage (PNC). Some advantages of PNCs over inorganic nanoparticles are their biodegradable properties and spatial controls for ligand displays on the exterior surface of the PNCs.

METHODS: The engineering of PNC interior, exterior, and inter-subunit interfaces is achieved through recombinant DNA technology. The engineered PNCs are produced in E. coli and purified using ion exchange chromatography method. The cell penetrating ability of the engineered PNC was examined in vitro on keratinocyte cell culture. After 1 hour incubation with fluorescently-labeled un-engineered and engineered PNC, the keratinocytes are imaged using confocal microscope and the number of cells with fluorescence was quantified with flow cytometry.

RESULTS: The interior of the PNC is engineered to allow attachment of active ingredients while the exterior is decorated with skin penetrating and cell entering (SPACE) peptides. pH-responsive property for the release of active molecules from the interior has been achieved by modifying the inter-subunit interfaces of the PNC with the amino acid histidines. The flow cytometry results show 2.5 fold increase of fluorescence in keratinocytes incubated with SPACE-engineered PNC compared to those of un-engineered PNC.

DISCUSSION: Engineering of the carrier to deliver active molecules to the skin for wound healing application requires meticulous design. In this study we have shown that PNC can be engineered for encapsulation of active molecules with triggered release property. For skin application, cellular penetration is enhanced by decorating the PNC with SPACE peptides. Further studies using orthologous skin model is underway.

Novel Bio-Based Plastics for Multiple Infection Prophylaxis Possessing Versatile Coating Performance

1Agricultural Science, Graduate School of Integrated Arts and Sciences, Kochi University, Nankoku, Kochi 783-8502, Japan

2Department of Agriculture, Faculty of Agriculture, Kochi University, Nankoku, Kochi 783-8502, Japan

3 Research Center, Toyobo Co., Otsu, Shiga 520-0292, Japan

Email: ashiuchi@kochi-u.ac.jp

INTRODUCTION: Poly-γ-glutamate (PGA), a hybrid-type polymer with a nylon-like backbone and polyacrylate-like side-chain structures, has reasonable biodegradability and good biocompatibility. We recently succeeded in the plasticization of hygroscopic PGAs using a simple but effective chemical transformation1), and is hereafter called the novel bio-based plastics PGA ion-complexes (PGAICs). The first material was characterized as a stoichiometric ion-complex, containing equally the carboxyl groups of archaeal (stereo-regular) L-PGA and a compound used in toothpaste called hexadecylpyridinium (HDP+) and had the potential to serve as a functional plastic showing a broad spectrum of antimicrobial activity1), but it is still unclear whether or not the extreme hydrophilicity of PGA can be suppressed using other cationic surfactant-candidates, e.g. dodecylpyridinium (DDP), benzalkonium (BZA) and benzetonium (BZT), as well as further examinations on the functionality of PGAICs for application in hygiene technology.

METHODS: Synthesis, structural analysis, and functional assays of PGAICs were performed using the methods described previously1). Anti-influenza/cytotoxicity testing of PGAIC was conducted with the technical support of the Kitasato Research Center for Environmental Science (Japan).

RESULTS: Other PGAICs than PGA/HDP, i.e. PGA/DDP, PGA/BZA and PGA/BZT, were obtained, and we further found their spontaneous coating performance to the surfaces of different materials (plastics, metals, and ceramics) as potent anti-staphylococcal and anti-Candida agents. This study also reveals that PGAIC is a promising candidate for anti-influenza coatings.

DISCUSSION: Because PGAIC is easily transformed into a nanofiberplastic1) in addition to a safe antimicrobial dispersant for material-surface coating, it may contribute to hygienic control and infection prophylaxis in various public facilities such as schools, hospitals, and transportations, re-sulting in a decreased risk of airborne infection, contagion, and serious pneumonia, which can be lethal. Moreover, these coatings can also aid against an unforeseen epidemic of new viral infectors.

REFERENCE: 1) Ashiuchi, M.et al. ACS Appl. Mater. Interfaces 2013, 5, 1619–1624.

Characterization and Biomedical Applications of Electrospun PHA-based Fibrous Membranes

Department of Chemical Engineering and Materials Science and Graduate School of Biotechnology and Bioengineering, Yuan Ze University, Chung-Li, Taoyuan 32003, Taiwan

R&D Center for Membrane Technology, Chung Yuan University, Chung-Li 32023, Taiwan

Email: cesunym@saturn.yzu.edu.tw

Polyhydroxyalknoates (PHAs) are a class of biologically synthesized polyesters. They possess many advantageous properties such as biodegradability, biocompatibility, nontoxicity and good mechanical properties, and have received much attention in biomedical applications. In this presentation, the characterization and biomedical applications of electrospun PHA-based fibrous membranes will be discussed. In particular, the crystallization of the PHA nanofibers was found to be restricted to specific crystalline planes due to the molecular orientation along the axial direction of the fibers. The crystallization behaviors of the electrospun nanofibers were significantly different from that of the cast membranes because of the rapid solidification and the one-dimensional fiber size effect in the electrospinning process. Mechanically, the electrospun PHA nanofibrous membranes were soft but tough, and their elongation at break averaged 240-300% and could be up to 450% in some cases. The degradation rate of the fibrous membranes could be adjusted by blending with poly(D,L-lactic acid) (PDLLA). It was found that the molecular chains of PHA and PDLLA were partially mixed in the amorphous phase, PDLLA didn't affect the growth of PHA crystalline phase, and PDLLA was excluded from PHA lamella stacks, i.e. in form of interstack segregation, in the blend fibrous matrix. Although PHA is suitable for biomedical applications, it often suffers from very poor cell affinity due to its hydrophobicity and lack of functional groups for covalent bonding with biomolecules. Hence, surface modification on PHA is a critical issue to increase surface activity and bioactivities. An example of dopamine, chitosan and autologous plate-rich plasma (PRP) surface modified PHA fibrous membranes was demonstrated to be effective for the healing and integration on tendon to bone interface.

References

References

- M.-L. Cheng, C.-C. Lin, H.-L. Su, P.-Y. Chen, Y.-M. Sun, Polymer, 49, 546-553 (2008)

- M.-L. Cheng, P.-Y. Chen, C.-H. Lan, Y.-M. Sun, Polymer, 52, 1391-1401 (2011)

Functional Bio-based Elastomers from Eucommia ulmoides

Graduate School of Engineering, Osaka University, Japan

Email: uyama@chem.eng.osaka-u.ac.jp

INTRODUCTION: Eucommia ulmoides accumulates trans-1,4-polyisoprene (TPI) in the leaves,

bark, root, and fruit coatings, which exhibits higher modulus and less flexibility than cis-1,4-

polyisoprene. This study deals with modification of TPI and applications of the modified bio-based

elastomers. Shape memory function provided the dynamically crosslinked network formation of

TPI.

METHODS: Grafting of maleic anhydride onto TPI was performed in 1,2-dichlorobenzene, and the

subsequent hydrolysis gave maleated trans-1,4-polyisoprene (MTPI). TPI containing primary

hydroxyl group (TPI-OH) was prepared by the reaction of MTPI and 3-amino-1-propanol.

RESULTS & DISCUSSION: Increasing trend of the grafted maleic moiety was observed with

increasing the concentration of maleic anhydride in the grafting reaction. With increase in maleic

content, the glass transition temperature of the resulting polymer increased, whereas the

crystallinity decreased. The maximum stress of the MTPI with carboxylates was larger than that of

the protonated MTPI. Above the melting temperature, the Young's modulus of MTPI with

carboxylates was higher than that of neat TPI and the protonated MTPI, due to dynamically

crosslinked network structure. Furthermore, the MTPI with carboxylates exhibited excellent shape

memory-recovery properties, exploiting the combination of the physical crosslinking and the

melting of the crystal. TPI-OH was crosslinked by blending with tin(II) octanoate. TPI-OH-Sn was

found to swell in tetrahydrofuran to form an organogel, whereas dissolve by adding hydrochloric

acid solution. Stress of TPI-OH-Sn was enhanced compared with that of TPI-OH. These materials

are expected to contribute to the development of bio-based intelligent elastomers.

PEGylated Silica Nanocapsules for Biomedical Application

Synthesis and Integration Capability Group, Institute of Materials Research and Engineering, Agency for Science, Technology and Research (A*STAR), Singapore

Email: x-li@imre.a-star.edu.sg

INTRODUCTION: A large variety of marine organisms, such as diatoms and sponges, form their silica skeleton in water at neutral pH and room temperature. Inspired by those biosilification processes, we have successfully developed a method to synthesize PEGylated silica nanocapsules at room temperature and near-neutral pH aqueous environment by using PEO-based block copolymer micelles as templates.

METHODS: The success of this approach lies on the confinement of silica shell growth at interface between core and corona of polymeric micelles as a result of encapsulation of silica precursors inside the core of the micelles. Functional silica capsules with fluorescent dye or magnetic particles encapsulated into their cores are prepared by mixing the dyes and particles with the PEO-based polymer and silica precursor.

RESULTS & DISCUSSION: The synthesized silica nanocapsules are intrinsically covered by a layer of free PEO chains, which enable them to exhibit excellent colloidal stability and antifouling property. The PEGylated silica nanocapsules are truly nanosized, which are ~15 nm in sizes, and demonstrated to be non-cytotoxic. These PEGylated silica nanocapsules can be further functionalized by encapsulating hydrophobic compound inside their core. For example, fluorescent conjugated polymers have been successfully loaded into the core of the silica nanocapsules. Magnetic silica nanocapsules have been prepared by encapsulating hydrophobic iron oxide (Fe3O4) nanocrystals in their cores. With low cyto-toxicity and high colloidal stability, the achieved silica nanocapsules are demonstrated to be excellent candidates for fluorescence and magnetic resonance cellular bioimaging

Ultrahigh-performance, Transparent Bioplastics Exceeding Conventional Petroplastics

1School of Materials Science, Japan Advanced Institute of Science and Technology, 1-1 Asahidai Nomi, Ishikawa 923-1292, Japan

2Graduate School of Life and Environmental Sciences, University of Tsukuba, Tsukuba, Ibaraki, 305-8572, Japan

3JST, ALCA, Tokyo102-8666, Japan

Email: kaneko@jaist.ac.jp

Bio-based polymers obtained by a polymerization of biomolecules are indispensable for establishment of green sustainable society where bioplastics would be applied in various fields. Improvement of functions and performances for bioplastics is very important. Polymer for high performance plastics are composed of aromatic backbones. However aromatic polymers based on petroleum industry were generally expensive. For example, aromatic polyamides and polyimides occupied series of highest heat resistant plastics whose price are much higher than food additives such as aspartame which is based on microorganismal fermentation. This comparison says that replacement of aromatic polyamide and polyimide from petroleum-base into bio-base reduced their costs and prices. On the other hand, conventional bio-based polymers were aliphatic like poly(lactic acid)s seriously completing against commodity-type plastics. In order to solve this problem, we have prepared aromatic polyesters from biochemical coumarate derivatives with rigid backbones, which demonstrating that cinnamoyl structure was rigid enough to show heat-resistance higher than 150 °C. [1-3]

Here we used 4-aminocinnamic acid (4ACA) which was bioavailable by a microorganism engineering. The photodimer of 4ACA was prepared via [2+2] cycloaddition, which is a kind of biological dianilines after carboxylate groups were protected by methyl esters or some groups. The dianilines were indispensable for preparation of the aromatic polyamide and polyimide but generally were very difficult to produce by a direct method of fermentation. The biodianilines were polymerized with diacids to produce aromatic polyamides and with tetraacid dianhydrides to produce aromatic polyimides. Especially the polyimides derived from the photodimer and cyclobutanetetracarboxylic dianhydrides showed a good thermomechanical performance as well as low density around 1.2 g/cm3, and additionally showed a high transparency [4]. These mechanical performances are higher than those of conventional transparent polymers, in spite of limited molecular design by bio-based molecules.

References

- T. Kaneko et al. Nature Mater, 5, 966 (2006).

- M. Chauzar, and T. Kaneko et al. Adv. Funct. Mater. 22, 3438 (2012)

- S. Wang, and T. Kaneko et al., Angew. Chem. Int. Ed. 52, 11143 (2013).

- P. Suvannasara, and T. Kaneko et al. Macromolecules, 47, 1586 (2014).

Seawater Based Industrial Biotechnology for PHA Production

School of Life Sciences, Tsinghua University, Beijing 100084 China

e-mail: chengq@mail.tsinghua.edu.cn

Due to the higher production cost, PHA can not compete with petrochemical plastics. Therefore, it is very important to develop low cost production technology for PHA marketing. Recently, we have succeeded in isolating halophile Halomonas spp. that are able to grow in seawater utilizing mixed substrates such as kitchen waste under unsterile and continuous processes. We have developed genetic engineering tool to assemble pathways for effective production of PHBV from glucose as the only C-source, and to change the bacterial shapes for making biomass recovery easier. The PHA production by synthetic Halomonas spp. based on seawater allows several important advantages including fresh water saving, energy saving, reduction on process complexity and increasing on process efficiency. This process can at least save 50% PHA production cost. At the moment we are conducting process scale up in an industrial setting.

References

- Dan Tan, Qiong Wu, Jin-Chun Chen, Chen GQ. Engineering Halomonas TD01 for Low Cost Production of Polyhydroxyalkanoates. Metabolic Engineering 26 (2014) 34–47

- Wang Y, Yin Jin and Chen GQ. Microbial Polyhydroxyalkanoates, Challenges and Opportunities. Current Opinion in Biotechnology 30 (2014) 59-65

- Yin Jin, Fu XZ, Wu Q, Chen JC and Chen GQ. Development of an Enhanced Chromosomal Expression System Based on Porin Synthesis Operon in Halomonas TD01. Applied Microbiology and Biotechnology DOI 10.1007/s00253-014-5959-1

- 4. Fu XZ, Tan D, Aibaidula G, Wu Q, Chen JC and Chen GQ. Development of Halomonas TD01 as A Host for Open Production of Chemicals. Metabolic Engineering 23 (2014) 78-91

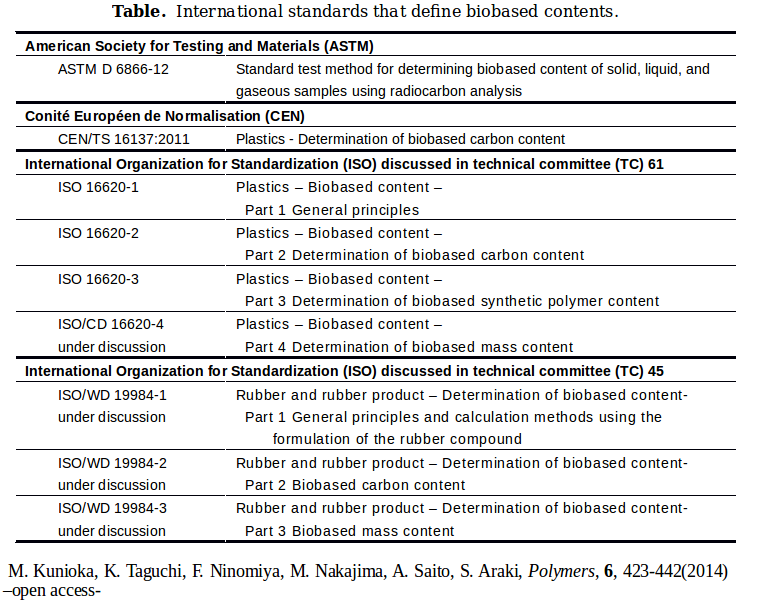

Determination of biobased content for plastics or rubber products and its ISO international standardezation

National Institute of Advanced Industrial Science and Technology (AIST), 1-1-1 Higashi, Tsukuba, Ibaraki, 305-8565, Japan

Email: m.kunioka@aist.go.jp

The biobased content is the index of the amount for biomass-based compound in plastics or rubber products. The determination methods of biobased contents such as biobased carbon content, biobased synthetic polymer content and biobased mass content based on ISO 16620 series for plastics or ISO 19984 series for rubber products were explained. ISO 16620 and 19984 series are discussed in ISO technical committee TC61 (Plastics) and TC45 (Rubber and rubber products).

Bio-based Polymers: From Research to Commercial Applications

Sinopec Research Institute of Petrochemical Technology, Shanghai 201208, China

Email: JamesWang.sshy@sinopec.com

INTRODUCTION: Effective utilization of natural polymers offers a potential solution to address the global sustainability challenge. However, the commercial applications of bio-based polymers often encountered economic and technology challenges including high cost, lacking performance and processability. Therefore, it is critically important to develop economically attractive and technically performing bio-based polymers to meet the market demand for green polymers.

METHODS: To achieve economic advantage and renewability, low cost natural polymers including cellulose and starch were used as starting materials, these material were first converted into thermoplastic cellulose (TPC) or thermoplastic starch (TPS) by chemical, biochemical or physical techniques. TPC and TPS were further engineered with a number of biodegradable or bio-based polymers to improve performance and melt processability. Highly compatibilized materials were also developed and evaluated.

RESULTS: Bio-based materials having good melt processability and properties were developed. These materials were based on TPC and TPS and a variety of biodegradable polymers. Innovative polymer processing methods were also developed. Both composition and process conditions were found to have significant effects on the performance and processability of bio-nbased materials. Unique microstructures and nano-structures were obtained which led to surprising improvement in material properties.

DISCUSSION: Engineered multi-component systems with desired balance of performance, cost and processability were important for developing industry-meaningful bio-based materials. Thin films were developed for sustainable packaging applications.

Synthesis and Properties of Polysaccharide Ester Derivatives

Science of Polymeric Materials, Department of Biomaterial Sciences,

Graduate School of Agricultural and Life Sciences, The University of Tokyo, Japan

CREST/JST, Japan,

RIKEN Institute/Spring-8, JAPAN

Email: atiwata@mail.ecc.u-tokyo.ac.jp

The increasing environmental and economic concerns on the utilization of petrochemicals have led researchers to rely on plant biomass as a feedstock for the synthesis of polymeric materials. Over the past decades, plant biomass has been recognized as one of the most important and cheap sources of renewable polysaccharides such as cellulose, chitin, and starch. It is well known that polysaccharides do not exhibit thermoplastic properties, because of their strong inter- and intra-molecular hydrogen-bonding.

Recently, our group succeeded to synthesize new thermoplastics from polysaccharides such as xylan, glucomannan, curdlan, pullulan, etc by esterification and found interesting thermal, mechanical, optical properties. Xylan is the most abundant hemicellulose with mainly beta-(1→4) linked xylose. Konjac glucomannan (GM) is isolated from tubers of Amorphophallus konjac plants and consists of beta-(1→4) linked D-glucose and D-mannose residues and the molecular ratio of glucose to mannose has been reported to be ca. 1.6. Curdlan is a linear polysaccharide with beta-(1→3) linked glucose produced by Alcaligenes faecalis. Pullulan is a water-soluble extracellular polysaccharide produced by strains of fungus Aureobasidium pullulans, consisting of a chain of maltotriose units that alternate regularly between alpha-(1→6) linkages.

In this paper, xylan, glucomannan, pullulan, and curdlan ester derivatives are synthesized and thermal and mechanical properties are investigated. Furthermore, in the case of xylan ester derivatives, a possibility as bio-based nucleating agents for PLLA and PDLA is presented.

Furthermore, more recently, we synthesized aromatic bio-based polymers from caffeic acid extracted from coffee beans and rice bran, respectively, and found some interesting thermal behaviors of these polymers.

Biodegradable Copolyesteramides of L-Lactic Acid and ε–Caprolactam Oligomers

1Department of Chemical and Materials Engineering, Faculty of Engineering, Rajamangala University of Technology Thanyaburi, Thailand

2Department of Biobased Materials Science, Kyoto Institute of Technology, Japan

Email: sommai.p@en.rmutt.ac.th

INTRODUCTION: An increase of plastic production is considered as a serious source of environment pollution from their wastes. Most of them are produced from fossil resource and are non-degradable. Recently, research and investigation have been focus on discover and development of new polymers that are friendly to environment. Poly(lactic acid), (PLA) is a biodegradable semicrystalline polyester having mechanical property comparable to the commercial polymers. However, PLA has limitations on its brittleness, insufficient impact strength and low thermal stability. In order to improve its properties, we studied the synthesis of copolyesteramide having amide parts in the lactic acid chains.

METHODS: Blocked copolyesteramide was synthesized from copolymerization reaction of L-lactic acid oligomers (OLLA) and ε-caprolactam oligomers (OCLM). The OLLA was synthesized via direct polycondensation of L-lactic acid using Tin (II) Chloride (SnCl2•2H2O) catalyst under reduced pressure. The OCLM was synthesized from ε-caprolactam using sodium hydride (NaH) catalyst under nitrogen atmosphere. Copolymerization of OLLA and OCLM with various ratios of OLLA:OCLM was carried out using N-Acetyl caprolactam catalyst. The effect of reaction temperature and pressure on component ratios and property of copolymer was studied.

DISCUSSION: The copolyesteramide synthesized was analyzed its chemical structure to confirm ratios of ester parts and amide parts in the polymer molecules. It was found that high polymerization temperature led to degradation of amide parts due to lower activation energy of reverse reaction of amide bonds than ester bonds resulted in less component of amide part remained in the copolymer molecules. The reaction time of copolymerization longer than 12 h also led to degradation of copolymer synthesized. The copolyesteramide can be used as a compatibilizer for blending of poly(lactic acid) and nylon polymer for polymer blends application.

Composite polysaccharide scaffolds for spatial distribution and sustained growth factor delivery

1Department of Biomedical Engineering, National University of Singapore, Singapore

2INSERM, U791 Center for OsteoArticular and Dental Tissue Engineering, Nantes, France

3Mechanobiology Institute Singapore, National University of Singapore, Singapore

4Department of Surgery, National University of Singapore, Singapore

Naturally derived polysaccharides are biocompatible, non-antigenic, non-immunogenic. Polysaccharides of non-animal origin such as pullulan, dextran, alginate and chitosan can easily recapitulate the polysaccharide component of the extracellular matrix in human tissues without potential disease transmission, and as such have important uses in tissue engineering. For instance, polysaccharides can be chemically crosslinked to form hydrogels with high water content to mimic soft tissues. Pullulan-dextran (PD) polysaccharide hydrogels are known to support endothelial progenitor cell growth. Due to the high charge density of polysaccharides, it is also possible to use them for the formation of interfacial polyelectrolyte complexation (IPC) fibers, which can be used for the sustained delivery of hydrophilic biomolecules. IPC fibers made with chitosan and alginate were previously demonstrated to regulate the temporal release of growth factors.